Overview

• Overview of API 682 and ISO 21049

• Designed to introduce the user to some of the significant features of the standard

• Module 1 of a four part series

• Each Module has an accompanying text which can bee seen by viewing the Notes Page (View/Notes Page from the Menu bar)

• Overview of API 682 and ISO 21049

• Designed to introduce the user to some of the significant features of the standard

• Module 1 of a four part series

• Each Module has an accompanying text which can bee seen by viewing the Notes Page (View/Notes Page from the Menu bar)

Module 1 Topics

• Review of API 682 First Edition

• Mission Statement

• API 682 Second Edition

• ISO 21049 and API 682 Third Edition

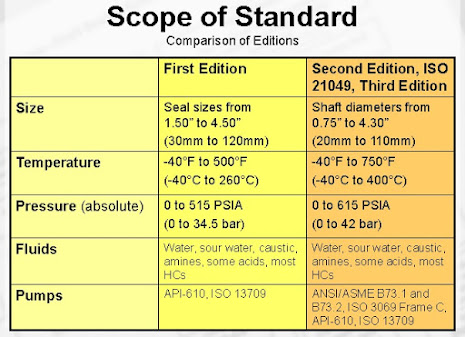

• Scope of Standard

• Key Concepts

• Seal Types

• Seal Arrangements

• Categories

• Review of API 682 First Edition

• Mission Statement

• API 682 Second Edition

• ISO 21049 and API 682 Third Edition

• Scope of Standard

• Key Concepts

• Seal Types

• Seal Arrangements

• Categories

Mission Statement “This standard is designed to default to the equipment types most commonly supplied that have a high probability of meeting the objective of a least three years of uninterrupted service while complying with emissions regulations.”

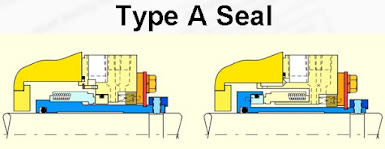

Seal Types

• Over the years, seal companies have released numerous designs and variations

• No standardization in seal designs, materials, or dimensions

• Challenge for API 682 Task Force was to create standard seal types defining seal design, materials, installation envelope, and operating windows

• Rotating flexible element, multiple springs, O-ring secondaries

• Silicon Carbide versus premium grade blister resistant Carbon

• Fluoroelastomer O-rings (FKM)

• Alloy C276 springs (316 for single spring option)

• Type 316 SS sleeve, gland, and other metal parts

• Throttle bushing in gland

• Rotating bellows, O-ring secondaries

• Silicon Carbide versus premium grade blister resistant Carbon

• Fluoroelastomer O-rings (FKM)

• Alloy C-276 bellows

• Type 316 SS sleeve, gland, and other metal parts

• Throttle bushing in gland

• Stationary bellows, flexible graphite secondaries

• Silicon Carbide versus premium grade blister resistant Carbon

• Alloy 718 bellows

• Type 316 SS sleeve, gland, and other metal parts

• Premium carbon floating bushing in gland

• Bronze anti-coke device

Rotating vs Stationary

• The default Type A and Type B seals have a rotating flexible element

• A stationary flexible element is an alternate

• The default Type C seal has a stationary flexible element

• A rotating flexible element is an alternate

• If surface speed at the faces exceeds 4500ft/min (23 m/s), a stationary flexible element must be used

Seal Arrangements

• The seal arrangement defines the

number or seals, their orientation, and

details about the seal’s operation

• Designations

• Contacting wet (CW)

• Containment seals (CS)

• Non-contacting dry-running

• Contacting dry-running

• Non-contacting (NC)

• Wet running seals

• Dry-running dual seals

Contacting Wet Seal - CW

• “Typical” mechanical seal

• Mechanical seal designed to run on liquid fluid film

• Does not intentionally create hydrodynamic forces

• Requires vapor suppression to keep fluid in a liquid phase

• Designed to run for a minimum of 25,000 hours

• “Typical” mechanical seal

• Mechanical seal designed to run on liquid fluid film

• Does not intentionally create hydrodynamic forces

• Requires vapor suppression to keep fluid in a liquid phase

• Designed to run for a minimum of 25,000 hours

Containment Seal - CS

• Designed as a dry running backup seal

• Outer seal in a dual non-pressurized arrangement

• May be either a non-contacting or contacting design

• Operates on buffer gas or vaporized process fluid

• Run for 25,000 hours at 10 PSI and at least 8 hours under process conditions

• Designed as a dry running backup seal

• Outer seal in a dual non-pressurized arrangement

• May be either a non-contacting or contacting design

• Operates on buffer gas or vaporized process fluid

• Run for 25,000 hours at 10 PSI and at least 8 hours under process conditions

Non-Contacting Seal - NC

• May be used as a primary seal or as a dual pressurized seal

• Seal is designed to create hydrodynamic forces to separate the faces under all operating conditions

• Designed to run for a minimum of 25,000 hours

• 1CW-FX or 1CW-FL configuration

• Single mechanical seal

• May have a fixed or floating throttle bushing

• May have single point or distributed flush

• 2CW-CW configuration

• Dual non-pressurized seal with a liquid buffer fluid

• Same as the First Edition Arrangement 2 seal

• 2CW-CS configuration

• Contacting wet seal with a dry running containment seal

• Containment seal may be either contacting or non-contacting

• 2NC-CS configuration

• Inner seal is designed to be non-contacting and operate with liquid, vapor, or mixed phase process

• Outer seal a containment seal

• 3CW-FB configuration

• Contacting wet seals oriented in a series (or face-to-back) orientation

• Default Arrangement 3 liquid seal

• Same as the First Edition Arrangement 3 seal

• 3NC-BB configuration

• Default Arrangement 3 gas seal

• Non-contacting gas seals in a back-to-back orientation

Categories

• Different applications may require different levels of seal sophistication

• Current practice of specifying “modified” API-682 seals

• Size restrictions based on pump construction

• Cost impact of seals

Three categories

• Category 1 – General duty services in chemical pumps

• Category 2 – Heavy duty services; similar to API-610 7th edition seals

• Category 3 – Heavy duty services; similar to API 682 First Edition seals