Power Generation (Bơm ứng dụng trong nhà máy điện)

The combined cycle power plant with its inherently higher efficiency and lower environmental impact is, in many cases, the optimum choice of today’s power generation industry. The Flowserve comprehensive lines of pump products and pumping systems are ideally suited for any combined cycle project, including co-generation of electrical power and steam.

Boiler Feed Water Services

The pinnacle of the Flowserve line for combined cycle boiler feed service is the multistage segmental

ring pump, which provides exceptional hydraulic performance, optimum efficiency and superior reliability. Additionally, Flowserve offers a variety of horizontal multistage pumps for boiler feed service. These include: axially split volute pumps; and double-case barrel pumps, in both diffuser and axially split volute configurations.

Condenser Cooling Water Service

Flowserve offers both horizontal and vertical pumps for condenser cooling water service. These are available in a wide range of hydraulic and material configurations. Non-pullout or pullout construction is available on vertical models.

Condensate Water Service

Vertically suspended, single- or double-suction, canned pumps with very low NPSHR provide workhorse duty in these difficult services. Horizontal pump designs are also available.

Auxiliary Services

Flowserve offers a complete line of horizontal and vertical pumps, including ANSI, ISO and

API designs. These may be specified in a wide variety of metallic and non-metallic materials to satisfy virtually all plant-wide pumping needs.

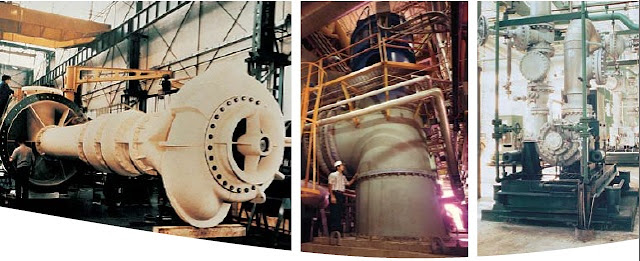

Fossil Fuel

Flowserve leads the market in supplying pumps and pumping systems for fossil fuel power generating

plants. No other pump company in the world can match the Flowserve systems knowledge, hydraulic

expertise or application know-how. Simply stated, Flowserve offers the power industry’s most comprehensive package of pump products, technical support and service.

Boiler Feed Water Services

Boiler feed is an extremely demanding service for pumps, and a boiler feed pump is one of the most

critical pieces of rotating equipment in the steam cycle. Flowserve has repeatedly proven that it builds the highest quality, most reliable boiler pumps available. Flowserve offers radially and axially split multistage pumps with single- or double-suction, first-stage impellers. Double-case barrel pumps, in both diffuser and volute configurations, are available for the highest pressure applications. Axially split multistage volute type pumps and radially split ring section diffuser type pumps are available to handle moderate pressure applications.

Circulating Water Services

Flowserve offers both vertical and horizontal circulating pumps in a wide range of configurations, hydraulics and materials to meet any application requirement. Pullout or non-pullout construction is available on vertical pump models. Concrete volute pumps are also available for these services.

Condensate Water Services

Flowserve has a long and proven performance record for this critical service. Its versatile line of condensate pumps offers unsurpassed hydraulic coverage and a broad range of options to address system requirements. Both single- and double-suction, first-stage, vertically suspended pump designs are available.

Flue Gas Desulfurization Services

Flowserve designs and manufactures pumps for all FGD system services. Some of these services include mill slurry pumps, reagent feed pumps, absorber recirculation pumps, absorber bleed pumps, demister wash pumps and filtrate pumps.

Auxiliary Services

Flowserve offers an extensive line of pumps, including ANSI, ISO and API designs. They are available in a wide variety of metallic and non-metallic materials and in many design and hydraulic configurations to satisfy virtually all plant-wide pumping needs.

Nuclear

Flowserve experience as a nuclear specialist dates to the birth of the nuclear power generation industry when it provided innovative pumping and sealing technologies under both the Byron Jackson heritage name and the IDP heritage name. Today, Flowserve continues the tradition with products and services that remain on the leading edge of technological advances in nuclear power. Capabilities include ASME Section III, Class 1, 2 and 3 pumps and nuclear mechanical seals, plus full repair, upgrade and maintenance service, technical and engineering support.

Primary Coolant Pumps and Seals

• Boiling water reactors

• Pressurized water reactors

• Heavy water reactors

Supplied or upgraded to rigorous technological and NSSS design standards.

Nuclear Safety Related Pumps

• Residual heat removal

• Containment spray

• Core spray

• Safety injection

• Charging and makeup

• Essential service water

• Auxiliary feed

• Miscellaneous nuclear

Conventional Pumping Services

• Reactor feed

• Steam generator feed

• Circulating water

• Condensate extraction

• Booster

• Auxiliary services

Boiler Feed Water Pumps

Multistage, Double-Case Diffuser Barrel Pumps CHTA

Between bearing, radially split, double-case diffuser, multistage designs

• Flows to 5220 m3/h (23 000 gpm)

• Heads to 4270 m (14 000 ft)

• Temperatures to 315˚C (600˚F)

• Pressures to 482 bar (7000 psi)

Multistage, Double-Case Volute Barrel Pumps HDB

Between bearing, radially split, double volute case, top-suction, top-discharge, multistage designs

• Flows to 5220 m3/h (23 000 gpm)

• Heads to 4270 m (14 000 ft)

• Temperatures to 315˚C (600˚F)

• Pressures to 482 bar (7000 psi)

Multistage, Segmental Ring Diffuser Pumps WXH

Between bearing, radially split, multistage designs

• Flows to 1160 m3/h (5100 gpm)

• Heads to 2750 m (9000 ft)

• Temperatures to 240˚C (465˚F)

• Pressures to 310 bar (4500 psi)

Multistage, Horizontal Split Case Volute Pumps DMX

Between bearing, axially split, dual volute case, side suction, side discharge

• Flows to 2950 m3/h (13 000 gpm)

• Heads to 2130 m (7000 ft)

• Temperatures to 205°C (400°F)

• Pressures to 275 bar (4000 psi)

Circulating Water Pumps

Flowserve offers a broad range of wet- or dry-pit vertical circulating water pumps for cooling water service. Horizontal design pumps and concrete volute pumps are also available.

Vertical, Wet-Pit Pumps VCT

Mixed flow pumps specifically designed for extended operation in condenser cooling water service; pullout and non-pullout designs

• Flows to 115 000 m3/h (500 000 gpm)

• Heads to 62 m (200 ft)

• Temperatures to 65˚C (150˚F)

• Pressures to 5 bar (75 psi)

Horizontal, Between Bearing, Single-Stage Pumps LNN

Axially split, double volute, double-suction pumps specifically designed for extended cooling water and circulating water services

• Flows to 51 000 m3/h (225 000 gpm)

• Heads to 300 m (985 ft)

• Temperatures to 150˚C (300˚F)

• Pressures to 30 bar (435 psi)

Concrete Volute Pumps BSV

• Pump assembly integrated into civil construction

• Pre-fabricated concrete sections form intake structure for the pump

• Pump types

––Mixed flow, open impeller

––Mixed flow, closed impeller

• Flows to 115 000 m3/h (500 000 gpm)

• Heads to 30 m (100 ft)

Condensate Extraction Pumps

Vertical, Multistage, Canned Pumps APKD & VPC

Multistage, mixed flow heavy-duty pumps with single- or double-suction first stage to fit NPSH requirements. Designed for continuous, extended operation.

• Flows to 4550 m3/h (20 000 gpm)

• Heads to 460 m (1500 ft)

• Temperatures to 132˚C (270˚F)

• Pressures to 55 bar (800 psi)

Flue Gas Desulfurization Pumps

Slurry Pumps

Flowserve offers a variety of horizontal type pumps for the difficult slurry handling services found in FGD applications.

Single-Stage Process Pumps

General purpose pump for slurries, light abrasives, severe chemical media

• Flows to 5000 m3/h (22 000 gpm)

• Heads to 100 m (325 ft)

• Temperatures to 150˚C (300˚F)

• Power from 2.2 kW (3 hp) to 600 kW (750 hp)

Rubber Lined and Hard Metal Pumps M

Horizontal, single end suction pumps with tangential discharge nozzles for severe duty requirements

• Flows to 10 000 m3/h (44 000 gpm)

• Heads to 90 m (300 ft)

• Temperatures to 120˚C (250˚F)

• Pressures to 10 bar (150 psi)

Absorber Recycle Pumps FRBH

Radially split pumps with front and back pullout design for recirculation services

• Flows to 17 500 m3/h (77 000 gpm)

• Heads to 40 m (130 ft)

• Sizes 600 mm (24 in) to 1000 mm (40 in)

Auxiliary Services Pumps

Flowserve can provide pumping solutions for virtually all power plant support services.

Chemical Process ANSI and ISO Standard Pumps Mark 3

Alloy

• Low flow, high head

• Sealmatic sealless

• Unitized self-priming

• Recessed impeller solids, slurries handling

• Magnetic drive sealless

• In-line

Non-Metallic PolyChem GRP

• High-grade, engineered composite

• Fluoropolymer PFA lined

• Mechanically sealed

• Magnetcally driven

API Process Pumps W & HPX

• Fully compliant with API 610, latest edition

• Horizontal, overhung, centerline mounted

• In-line configuration with in-line suction and discharge nozzles

• Additional configurations

––Radially split, single-stage, double-suction, dual volute

––Low flow, high head

––In-line with a separate bearing housing

––In-line modular design

Additional Pump Types

• Reciprocating pumps

––Horizontal

––Vertical

• Rotary

––Gear

––Twin screw